Introduction

The cost-to-capacity method can be a very useful tool when developing elements of the cost approach in many valuations. It is a order-of-magnitude cost estimation tool that uses historical costs and capacity in order to develop current cost estimates for an entire facility or a particular piece of machinery or equipment [1]. The fundamental concept behind the cost-to-capacity method is that the costs of facilities of similar technology but with different sizes vary nonlinearly. More specifically, cost is a function of size raised to an exponent or scale factor [2]. The governing equation is as follows:

The raised scale factor in Equation 1 above accounts for the nonlinear relationship and introduces the concept of economies of scale where, as a facility becomes larger, the incremental cost is reduced for each additional unit of capacity [3].

However, not all facilities actually experience economies of scale related to costs. A scale factor of less than 1 indicates that economies of scale exist and the incremental cost of the next added unit of capacity will be cheaper than the previous unit of capacity. When the scale factor is greater than 1, economies of scale do not exist; rather, diseconomies of scale exist and the incremental cost becomes more expensive for every added unit of capacity. A scale factor of exactly 1 indicates that a linear relationship exists and there is no change in the incremental cost per unit of added capacity [4]. A scale factor of 1 also indicates that it is just as economically feasible to build two small facilities as one large facility with the same capacity [5].

Application

One of the main advantages of the cost-to-capacity method is its relatively easy application. It can be applied to quickly develop reasonable order-of-magnitude cost estimates. However, there are a number of considerations that must be addressed prior to applying the cost-to-capacity method.

To obtain reasonable results, the technology of the facility for which the cost is being estimated must be the same as, or very close to, that of the facility with a known historical cost. Likewise, the scale factor that is applied must appropriately reflect both the technology of the known and cost-estimated facilities. The scale factor that is used should also be specifically applicable to the range of sizes for the specific technology of facility being analyzed.

In addition to technology, the analysis must consider the configuration of the facility, its location, and any unique design and site characteristics. Differences in location would almost always require the application of a locational cost adjustment factor. Likewise, different configurations or unique design or site characteristics would require a cost adjustment prior to completing the cost-to-capacity analysis. Significant deviation between the known and estimated facilities in any of the aforementioned categories can yield nonmeaningful cost estimate results [3].

Lastly, prior to applying the cost-to-capacity method, the known historical costs that have a specified reference year must be adjusted for inflation in order to develop a correct cost estimate for the required year. For example, it may be required to develop a cost estimate for a piece of industrial equipment in current dollars but the known costs are based on 2010 dollars. In general terms, to appropriately account for the effects of cost inflation, the known historical cost must be escalated using cost indices applicable to the technology in question [3].

Example

In order to better illustrate the previously discussed concepts and methodologies, a simple application example of the cost-to-capacity method is given below:

An order-of-magnitude cost estimation is needed for a proposed 1,240-megawatt (“MW”) combined cycle power plant, as of January 2013. Research indicates that a combined cycle power plant with a capacity of 620 MW with the same technology had construction completed in 2011 in the same regional area. The total cost of the existing plant in 2011 dollars was approximately $580,000,000. It is determined that, in addition to being located in the same region, the existing plant is almost identical to the proposed plant in terms of overall design, with the exception of having fewer units. Thus, it is concluded that the historical cost of this plant is a good reference for the required cost estimation. Because the existing plant is located in the same regional area, no locational adjustment is required; further, the almost identical design requires no additional cost adjustment for unique design characteristics. The only adjustments that need to be taken into account in this cost estimation are cost inflation and size scaling.

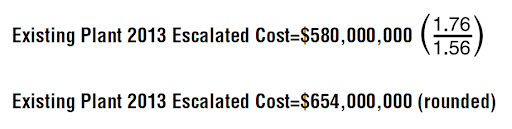

First, the 2011 dollars must be converted to 2013 dollars. An applicable index related to costs associated with combined cycle power plants must be referenced. An appropriate index indicates a 2011 index value of 1.56 and a 2013 index value of 1.76. Thus, the 2011 historical cost must be escalated to 2013 dollars as shown below:

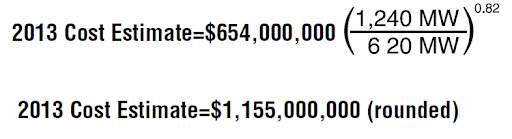

Next, the escalated cost must be scaled to account for the difference in size between the proposed plant and the existing plant. A credible source indicates that an appropriate scale factor to apply in cost estimates for combined cycle power plants is 0.82. The previously introduced Equation 1 can now be mathematically manipulated and solved as follows:

As represented by the above cost estimate example, a size increase of 2 times results in a cost increase of approximately 1.77 times. This expresses the previously introduced concept of economies of scale inherent in applying a scale factor of less than 1. Similarly illustrated is the fact that as the capacity of the power plant in this example increases, it becomes incrementally cheaper for each additional unit of added capacity.

References

- Ellsworth, Richard K., “Capacity Factor Cost Modeling for Gas-Fired Power Plants,” Construction Accounting & Taxation, vol. 19, no. 1, Jan/Feb. 2009, p. 31.

- Humphreys, Kenneth K., Jelen’s Cost and Optimization Engineering, McGraw-Hill, Inc., New York, NY, 1991, pp. 382-383, 386.

- U.S. Department of Energy, National Energy Technology Laboratory, Office of Program Planning & Analysis, Performance Division, “Quality Guidelines for Energy Systems Studies, Capital Cost Scaling Methodology,” January 1, 2013, pp. 1-4. Retrieved from http://seca.doe.gov/energy-analyses/quality_guidelines.html.

- Ellsworth, Richard K., “Cost to Capacity Factor Development for Facility Projects,” Cost Engineering, vol. 49, no. 9, Sept. 2007, p. 27.

- Dysert, Larry R., “Sharpen Your Cost Estimating Skills,” Cost Engineering, vol. 45, no. 6, June 2003, p. 23.

The content of this blog was previously published in the MTS Journal.